LASER CUTTING

Laser cutting

I have learnt quite a few things about the laser cutter machine, one of which is how it works and its safety principles! 😷 I need to emphasize that safety is a very IMPORTANT factor, as this concerns everyone that is working in the workplace. I will get onto the safety reasons once i am done on how this cool machine works !

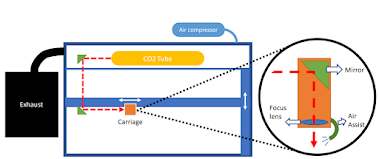

First of all, this is how a machine will look like in a simple diagram. How it works is that, carbon dioxide is used to generate the laser beam. The beam is then reflected by the mirrors onto the carriage where it reaches the focus lens. This intensify the laser to give it enough power to cut through hard and strong objects!SAFETY is very important as this concerns everyone in the workplace, including yourself 👊, so it is crucial to learn a safe way to handle and practice safe measures while using laser cutting machine.

- Don't stare into the beam while cutting 👀

- Don't use materials that contains Chlorine (e.g. PVC) or Foam

- Don't cut or engrave Metal materials

- Never to leave machine unattended while cutting/engraving

- If small fire occur, attempt to extinguish by blowing it or remove material from laser cutter

- If Material cannot be cut through,

- stop and check ✋

- Focus lens might be dirty, continue use of dirty lens will result in cracked lens! 😉

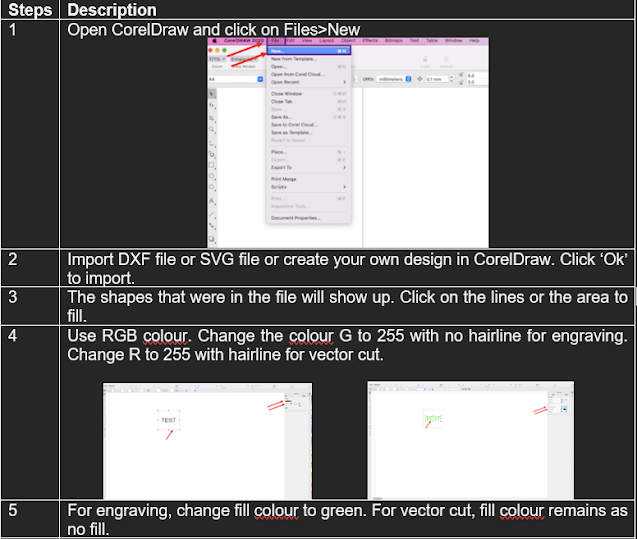

Apart from those, i also have learnt how to use coreldraw and its functions, which will aid me in using the laser machine, which i will go through how to use it later in the blog! 😆

Improved Standard Operating Procedures(SOP) of EPILOG FusionPro

During the actual experiment, unlike the other teams, our team used the FusionPro laser cutter instead of the M2 version. Our group only prepared SOP for the M2 version, thus we were faced with some difficulties during the competency test. After the first round, we did some modifications and made some improvements!

Start-Up Procedures

Shutdown Procedures

Apart from that, we made some calculation error for the holes thus the pieces do not connect well together... Nonetheless, we learnt from our mistakes and learnt that we should use kerf the next time we do this practical if we ever have a chance to do it again! 👍

Here is our design for the laser cutting! its a weighing scale💦 And our final product :)

ReflectionIn general, i have learnt a lot of new things in this practical. One main thing that i have learnt is how to use laser cutter effectively and efficiently. I can tell a lot of difference before and after practical, that the more i practice the more i am used to using the laser cutter and it is way easier than i think. It was hard for me at first but it gets easier !😊 I made a lot of some minor mistakes here and there. One of the mistake i made was forgetting to change back to no hairline for vector, that caused me to redo the entire competency test again 😓. I got it right the second time though, everything went smoothly as planned as i have learnt from my mistakes! ✌ This is what i had made during the competency test, its a heart!!!

Reference

- Epiloglaser.com. 2021. Fusion M2 32/40 Technical Specifications. [online] Available at: <https://www.epiloglaser.com/laser-machines/fusionm2-techspecs.htm> [Accessed 27 October 2021].

- Vector-conversions.com. 2021. Raster (Bitmap) vs Vector. [online] Available at: <http://vector-conversions.com/vectorizing/raster_vs_vector.html> [Accessed 27 October 2021].

Comments

Post a Comment